An outer rotor brushless motor (vs inner rotor design) is a type of electric motor that uses a permanent magnet rotor, or outer rotating component, instead of a traditional armature, or inner rotating component. This design allows for a more efficient and powerful motor. The magnetism of the outer rotor can be more easily controlled and directed towards the stator, or stationary component, to produce torque. We cover just what is an outer rotor brushless motor and how it compares to inner rotor designs.

Starting with some contrasts. An inner rotor brushless motor has the armature, or inner rotor, as the magnetized component. This can be less efficient and requires more energy to produce the same amount of torque as an outer rotor brushless motor.

Overall, outer rotor designs offer several benefits compared to inner rotor designs. This includes higher efficiency, longer life, and better performance at high speeds. These characteristics make them well-suited for use in outdoor power tools. With these tools, long run times and high power output rule the day. This presumes the design doesn’t require a more narrow or compact motor.

We spoke with Carlos Quintana, Senior Product Manager of Makita’s Cordless Tools division to get an idea of the difference along with the pros and cons of both designs.

General Design Differences

The fundamental difference between inner rotor vs outer rotor brushless motors is in their design. All brushless or brushed motors, function through the use of magnets. The stator’s function is to generate a charge that will either attract or repel the magnets. This causes the motor to rotate. The rotor, which holds the magnets, is the component that spins.

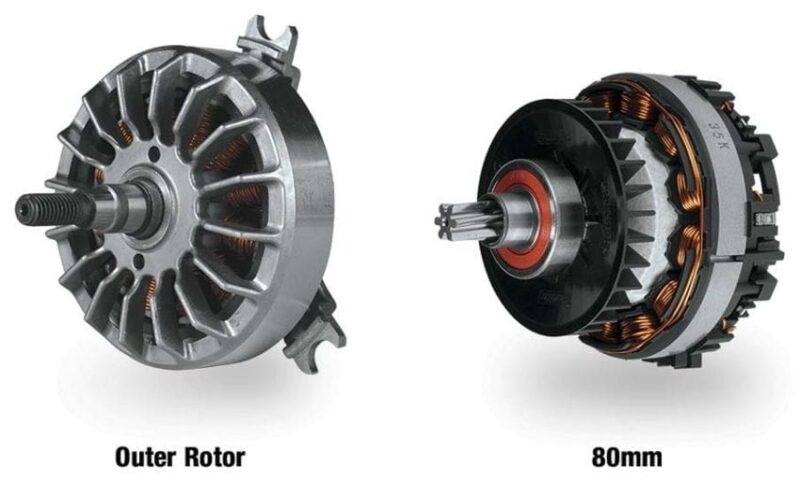

In an inner rotor design, the stator is located on the exterior and the rotor is positioned on the interior. In an outer rotor brushless motor, the positions of the stator and rotor are reversed. The rotor exists on the outside with the stator positioned on the inside.

Outer Rotor Brushless Motor Design Consequences

Inner vs Outer Rotors Footprint

If you were to compare two motors with the same power output and overall diameter, one inner rotor and one outer rotor brushless, how would they compare in terms of size and appearance?

Both motors would require the same amount of magnetic surface area. However, because the magnets in an inner rotor design are located on the interior, the diameter of the motor would be smaller. This means it needs more length in order to accommodate the magnets.

On the other hand, an outer rotor brushless motor has the magnets attached to the exterior, so the diameter is wider. This allows the overall length of the motor to be shorter and results in a natural reduction in weight.

Efficiency

Inner rotor motors have a natural tendency to wobble, which can cause them to ride in and out slightly within the stator and reduce their efficiency. Some manufacturers, like Makita, have implemented techniques like adding ridges to stabilize the rotor and increase efficiency to 99%. However, not all manufacturers use such measures. In contrast, outer rotor brushless motors do not experience this wobble and are inherently more efficient due to their design.

Balancing the Benefits

When you opt for an outer rotor design, you have two options. One option is to reduce the length and weight of the motor while maintaining the same power output, but with increased efficiency. Alternatively, you can keep the weight the same and achieve more power while still benefiting from the efficiency gains.

It’s also possible to find a balance between the two, reducing some of the weight while slightly increasing the power output. This is often seen in battery-powered string trimmers, which can benefit from the lighter weight of front-loaded brushless motors.

Outer Rotor Brushless Motor Tool Applications

Most brushless tools utilize an inner rotor design in order to reduce the overall size (diameter) of the motor. Makita uses a minimum of four different inner rotor brushless designs: 80mm, 54mm, 44mm, and 38mm.

The Makita 18V X2 string trimmer and chainsaws get a different (fifth) design. It features a large 80mm outer rotor brushless motor. These tools have the necessary room to utilize those “girthier” motors. At the same time, the narrower depth shrinks the overall footprint of the motor.

That wide-but-shallow profile lets Makita utilize a direct drive system. This gives those tools the added advantage of a truly efficient power transfer system.

Looking Forward to More Outer Rotor Brushless Motor Tools

As manufacturers continue to convert traditionally corded tools to cordless versions, you can expect to see an increase in the use of outer rotor brushless motors. Lithium-ion technology has not yet reached its full potential, and outer rotor designs can help generate more power and efficiency as we explore the limits of what battery power can accomplish.